Future Trends in Marine Engine Manufacturing: What to Expect by 2030

- Raktim Das

- Jun 16

- 3 min read

The global maritime industry is going through a phase of transformation. It is driven by regulatory pressures, environmental concerns, and technological advancements. The demand for lower emissions, higher efficiency, and digital integration has grown over the years. Now is the time for marine engine manufacturers and venture capitalists to embrace advanced Marine engine technologies.

Studies suggest that the Marine Engine Market Size is expected to expand by USD 15,642.8 million by 2030. The vast number highlights the strong importance of taking more stringent steps in the marine engine manufacturing industry.

The Push for Cleaner Marine Engines

If you look back at the past, you will notice that marine engines have been a significant contributor to air pollution. Land-based emissions have been successful in industrialized nations through policies and technological upgrades. However, maritime emissions remained relatively unregulated until the late 20th century.

The global community started acknowledging the marine industry’s impact on nitrogen oxides (NOx), sulfur oxides (SOx), and carbon dioxide (CO₂) emissions in the 1990s. Over the years, policies on marine pollution have become stricter. Marine Engine Manufacturers are adapting now to new trends in manufacturing.

Emerging Trends in Marine Engine Technology

1. Electrification and Hybridization

Electric and hybrid propulsion systems are gaining traction due to their ability to reduce greenhouse gas emissions and operating costs. The recent advances in battery technology have shown the potential for larger energy storage capacities.

Hence, hybrid-electric systems for short-sea shipping and even certain offshore applications have become feasible. By introducing these systems, marine engine manufacturers can reduce fuel consumption, and provide quieter, smoother operations.

2. Alternative Fuels

There is a significant shift toward adopting cleaner fuel alternatives. Liquefied natural gas (LNG), hydrogen, ammonia, and advanced biofuels are increasingly used to replace conventional heavy fuel oil (HFO). However, the choice of fuel often depends on voyage length, vessel type, and available infrastructure.

Each fuel offers its own set of advantages:

LNG lowers SOx and NOx emissions

Hydrogen and ammonia can potentially eliminate carbon emissions altogether

3. Digital Integration and IoT

Digitalization is reshaping the marine engine landscape. IoT-enabled sensors, real-time monitoring systems, and AI-driven analytics are becoming standard features in modern marine engines.

These technologies allow for predictive maintenance, fuel optimization, and performance benchmarking. As a result, downtime is minimized and operational efficiency is maximized, contributing to both cost savings and environmental performance.

4. Autonomous and Unmanned Vessels

Autonomous shipping is not just a futuristic concept—it’s already underway. Marine engines must adapt to the unique requirements of unmanned vessels, such as remote diagnostics, fault tolerance, and reduced need for manual oversight. These engines emphasize reliability and real-time communication with control centers, using advanced software for automated navigation and power management.

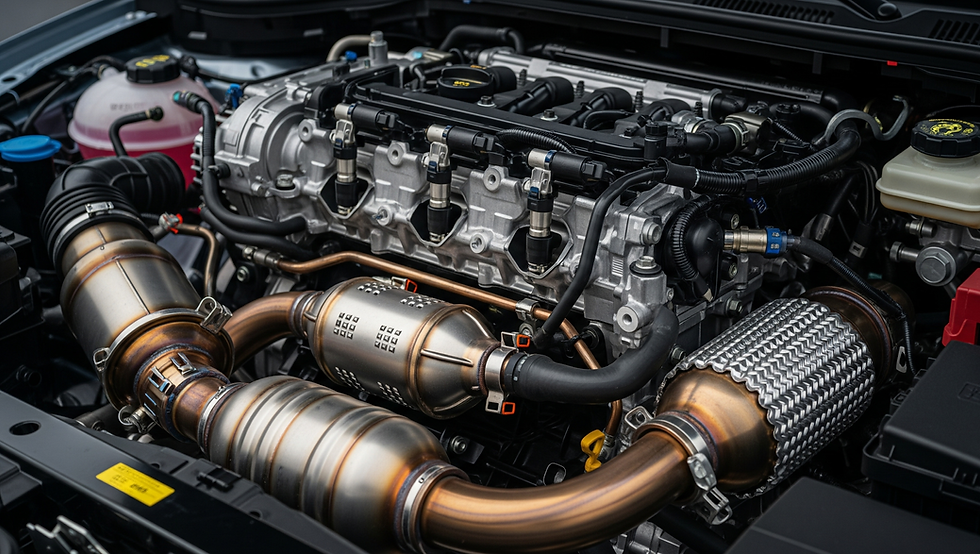

5. Emission Reduction Technologies

End-of-pipe solutions such as exhaust gas cleaning systems (scrubbers) and Selective Catalytic Reduction (SCR) units are being installed on both new builds and retrofits. Scrubbers effectively remove SOx from exhaust gases, while SCR systems convert NOx into harmless nitrogen and water.

While effective, marine engine manufacturers must design considering the limited space available onboard ships and must account for the safe handling of byproducts.

6. Modular and Scalable Engine Designs

The need for customizable solutions has led to the rise of modular propulsion systems. These engines offer flexibility in terms of fuel type, power output, and component integration.

This modularity supports easier upgrades, improved serviceability, and optimized vessel design. It also allows shipowners to future-proof their fleets against evolving regulatory and market demands.

7. Lifecycle Management and Circular Economy

Marine engine manufacturers are increasingly focusing on sustainable lifecycle practices. This includes designing engines for longer operational lives, reusing components, and enabling recycling of materials at end-of-life. Engine remanufacturing and refurbishment are gaining popularity, offering a cost-effective and eco-friendly alternative to new builds.

The bottom line

Marine engine technology is at the heart of the maritime industry’s shift toward sustainability, digitalization, and automation. Marine engine manufacturers are exploring new technologies such as hybrid propulsion, alternative fuels, IoT integration, and modular design to reshape how vessels are powered and managed. So, by 2030, the industry will significantly reduce global pollution.

Comments